All Tig Welding putting Charters Towers on the map - FULL ARTICLE

Excerpt from Sumpton’s Gold Rush Gazette - Friday 6th of June 2025

Charters Towers’ All Tig Welding, led by Clayton Young, has gained national reach with its Ally Cat vehicle accessories.

Using advanced technology like 3D scanning and CNC machining, the business now supports major projects while creating local jobs.

In the interview below, Clayton Young, Owner and Director, shares how the business has evolved from a small aluminium workshop into a technologically current operation using 3D scanning, CNC machining, and additive manufacturing.

He also discusses their involvement in major national projects and highlights the importance of supporting local jobs and training future generations.

For those interested in reading about how All Tig Welding is contributing to Australia's manufacturing sector, this interview offers insight into a local business with national reach.

All Tig Welding staff Levi Steenson, Newson Strickland, Drake Donnison, Owner Clayton Young, Thomas Lawrie, Bruce Hauff, Jay Rowe, and Assistant Manager Lauren Sawtell (Absent: Paul Bailey)

Q: What modern equipment and technology do you utilise at All Tig Welding within Charters Towers, and how has this equipment developed your business?

A: All Tig Welding is a local Australian Made business located in Charters Towers which has a diverse range of manufacturing methods and processes. Originally a manufacturer solely in aluminium accessories for ATV and UTV, the business now utilises advancements in technology involving reverse engineering, 3D scanning, CNC routers, additive manufacturing, and advancements utilising CAD, Inventor, and other software programs.

We now provide a large range of vehicle accessories to our customers incorporating additive manufacturing, which in turn has allowed us to provide our customers with the highest level of protection for their vehicles available. This has revolutionised the level of protection, drawing further recognition to the quality of our Australian Made products.

With continuous advancements toward our adoption of automated systems, resulting in greener and less labour-intensive manufacturing methods, we are privileged to be working with the Queensland Manufacturing Hub, most recently attending the Australian Manufacturing Week in Melbourne earlier in May after being invited to attend as Queensland delegates.

Due to this opportunity, we have the privilege of connecting and working with a multitude of national technologically advanced manufacturing businesses, with the significance of a manufacturing supplier for the Gilmore Space Project, due to be launched from Bowen Orbital Spaceport.

This was an incredible experience and only enhanced our drive to strengthen Australian manufacturing and to provide employment opportunities to members of our community and in the region.

Ally Cat manufacturing at All Tig Welding in Charters Towers

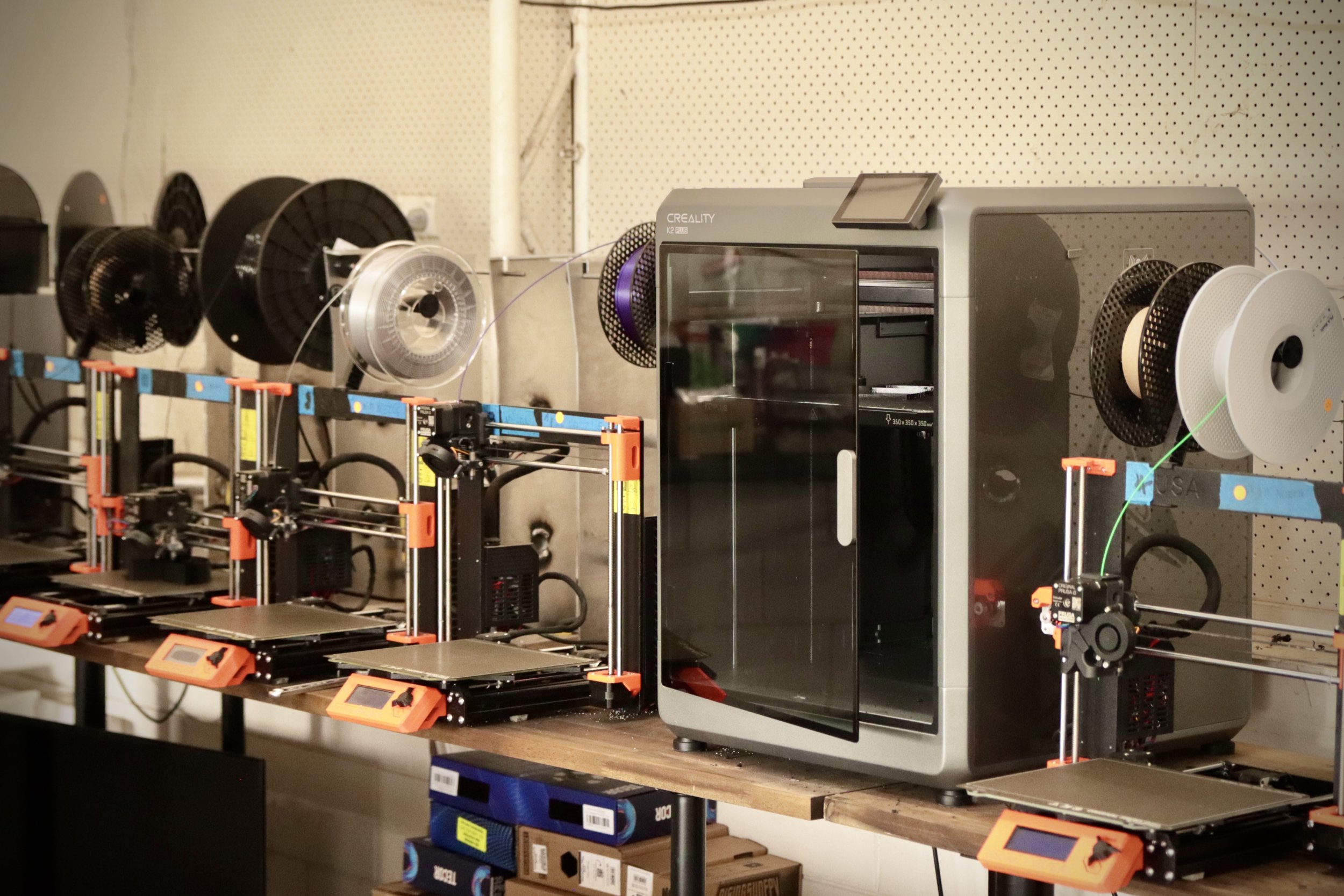

3D Printers used for manufacturing at All Tig Welding in Charters Towers

Q: What is your software background/experience and how has it facilitated your current business practice?

A: For the growth and success of All Tig Welding to occur the need to become self-taught in CAD software, (Computer Aided Design), was required. Originally beginning to learn CAD in 2008, as the business has grown over the last 10 years with the creation of Ally Cat, integration of other software systems has also become crucial to the advancement of our Ally Cat accessory designs. Learning new software and how to utilise this into aspects of the business has taken a large amount of time and patience, with no courses or lessons taken to learn these programs.

Our business works with a consistent need for R&D and product development, providing employment opportunities for people in a diverse range of areas, not just aluminium manufacturing.

Q: What are the main services of interest you provide?

A: Our primary service is the national wholesale of Ally Cat accessories. While we endeavour to assist other Charters Towers businesses and the community, we generally work business to business.

With the ability to provide services requiring CNC cutting, additive manufacturing, mandrel bending and CNC press, we are happy to help if our machinery is suitable for the requirements and can be scheduled to align with our primary business methods.

Q: What is your message to Charters Towers locals?

A: We would like to support and educate the future generations heading into the workforce that Charters Towers business can has and can provide cutting-edge technology and employment opportunities that rival larger cities.